“Moving Mountains” To Secure Supply Against All Odds

Ever since the onset of the pandemic, we have gotten used to products being sold out at supermarkets or waiting longer for our orders. Behind the scenes, product supply organizations are giving their best to tackle unprecedented challenges as some things are simply too important to be missing. At Bayer, teams around the globe have been going the extra mile to ensure that vital products reach their customers in time – so that farmers can continue to grow our food and patients can rely on their medication.

While some areas of public life are returning back to normal, logistics and supply chains are still severely impacted by the disruptions initially set in motion by the Covid pandemic. Volatile supply, unpredictable inventories, backed up containers, labor shortage and reoccurring lockdowns as seen in China in spring 2022 are among the reasons that the situation is far away from going back to “normal”. And the Russian invasion in Ukraine has contributed its share to thwarting any hopes for recovery that may have arisen at the beginning of 2022.

Companies throughout the globe are struggling to source their materials and get their products out to their customers. In a survey conducted by the German ifo Institute in June 2022, 74.1 percent of participating industrial companies in Germany said they were facing production disruptions due to procurement challenges. At Bayer, teams in Product Supply and Commercial Operations have found creative ways and redoubled their commitment to fulfill their obligation to customers and to keep the production running.

By saying goodbye to the old way of doing things, embracing change and creative solutions, always having a plan B in place and maintaining a great team spirit, they are on their way of moving from constant firefighting to sustainable resistance.

Several Bayer employees have shared their stories of how they are mastering the situation.

Even without disruptions, Supply Manager Ewa Karaszewska and her team at Bayer Pharmaceuticals, located in Basel and Barcelona, face a particular supply challenge with the Xofigo cancer therapy: Xofigo is radioactive and has an extremely short shelf-life. From the moment production starts, Xofigo has to be inspected, packaged, released and distributed to hospitals around the world within 28 days, while each patient treatment is precisely scheduled in advance.

Ever since the regular distribution network was severely disrupted at the onset of Covid, the global Xofigo Team has been focusing on strengthening supply chain flexibility in order to adapt to new partners and dynamically changing processes. A prime example was the challenge to supply patients in Taiwan when the usual supply route – shipments of Xofigo manufactured in Norway – was suddenly blocked due to Covid-related travel restrictions.

“In April 2020, our U.S. plant, an alternative source, was about a year away from operational readiness for this market, not even approved by Taiwan authorities. We addressed this challenge from two sides: one approach was to get Taiwan’s FDA to approve Xofigo manufactured in the USA and the other was to intensify efforts to find an airline for Xofigo shipments from Europe to Taiwan,” Ewa explains. “It was a very proud moment when it became clear that we achieved both goals: received exceptional approval to manufacture for Taiwan in the USA and managed to resume shipping from Europe with an alternative airline.”

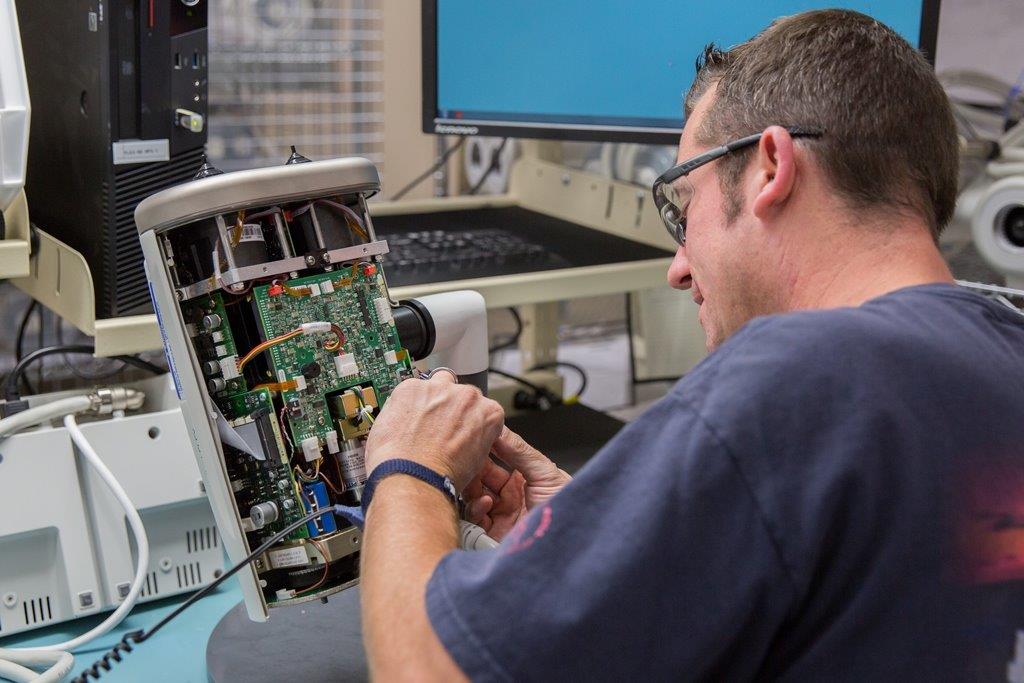

Mandy Mohrbach, Senior Supply Chain Operations Manager based in Pittsburgh, USA, and her team have been facing serious sourcing challenges ever since the pandemic started. They are responsible for the radiology segment at Bayer’s Pharmaceuticals division. “Many parts for our products are very specialized, molded or machined explicitly for us and most of them are single-sourced. And most vendors are still catching up from the pandemic, facing labor shortages and other problems to meet the high demand,” she explains.

The PS organization set up a four-pillar plan to source the necessary parts to maintain production and service spare part needs. Apart from chasing for parts on the open market and simplifying the onboarding process for new suppliers, an initiative to reuse parts from old products that used to be scrapped helps to build and repair equipment. Repair, reuse, recycle is the motto – which not only benefits the supply situation but also contributes to sustainability. “We are proud that we could stick to or even exceed our lead times. We plan to manufacture 10.000 injectors this year where we initially thought we would only reach 4.000. To achieve this, we are moving parts around globally and coordinate closely with our field service colleagues who are also going the extra mile to get our equipment out to the customers,” says Mandy.

While most of the world is trying to adapt to a “new normal”, Shanghai has just seen a new lockdown, one of the longest and strictest in the city’s history. From the end of March to early June 2022 the whole city came to a standstill, the airport was congested with cargo and people were requested to stay at home.

Even though the head office of Bayer’s Consumer Health division is located in Shanghai, the logistics and supply chain team managed to quickly get deliveries back to normal levels, reaching 96 percent of the case fill rate already in April and 99 percent in May.

“It was a big team effort and only worked because of the resilience and agility of the supply chain that had built in the past two years as well as the great cooperation between our teams and external partners. This is what we learned from the pandemic,” reports Stephen Tang from the Consumer Health logistics department. “We rerouted import shipments to Beijing, reallocated inventories to Guangzhou RDC, combined small orders into larger ones and secured as many special transportation permits from the authorities as possible.”

At the beginning of the COVID pandemic demand for Aspirin in Latin and Central America surged – for Mauricio Gonzalez, Head of Supply Chain Management at the Consumer Health production site in Lerma, Mexico, this is usually good news. But it came at a time, when suppliers, ports, distribution centers and factories were characterized by the absence of their workforce and minimum capacity due to COVID.

“We couldn’t forego this opportunity and did everything in our power to be able to produce and deliver enough Aspirin. We approached colleagues in the USA, where the demand was not as high at that moment, and they put their ingredients at our disposal. Long-lasting relationships with our suppliers, training people in record time to cover labor gaps with temporary personnel and switching to airfreight instead of sea freight were some of the creative ways that helped us manage the situation,” recalls Mauricio. “One time, when a supplier told us the aluminum foil he had sent us was partly defective, we should just scrap it, my colleagues spent an entire weekend to identify and separate all the usable parts. We simply could not wait for the new shipment.”

At Crop Science, Bayer’s agricultural division, employees in supply chain functions have been facing many challenges during the past three years: COVID-19 led to lockdowns almost everywhere, the Suez Canal was blocked and then Hurricane Ida hit the Luling production site in Texas in August 2021, leading to a complete shutdown for several weeks. When that happened, the business in Latin America had thus already been impacted by port omissions, shortages of labor, and missing containers – leading to an Ocean Freight reliability index of only 32 percent, a 10-year record low.

With the corn and soybean growing season ahead, governments and grower associations in the region were in alert mode as they rely on Bayer’s herbicides and seeds. “When your entire status quo is challenged, you have to think outside the box,” stresses Kyu Kim, LATAM Regional Planning Head. “We set up a cross-functional ad-hoc task force and three months later, 150 containers were en route to Latin America.”

The solution was unprecedented: The team had chartered its own ship! In addition, 16 airplanes were chartered, and more than 220 commercial flights used to transport 2,500 tons of active ingredient of fungicides to Brazil. “In Product Supply we are moving mountains to deliver our products to customers,” says Kim.